So small models or figurines, down to 25mm tall will turn out convincingly? I'm more interested with accuracy then size. For some things the stated precision (~.002/.004") is insufficient. But you can't expect the world for 160$.

I have several 3D printers (Flashforge, Creality 10S ProV2, etc..) as well as Resin (Qidi and Elegoo). Why do I have several? Because once you start, you keep upgrading to next next bigger/better model with nice to have features LOL!

I'm on the same bandwagon several others have suggested:

Resin for miniatures - better detail than FDM

Be prepared for the potential mess of resin, curing, etc etc. ..

Elegoo or Qidi for me - low price points

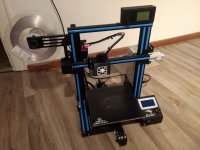

For FDM, I love my FlashForge for the dual print heads (I keep PLA on one and ABS on the other) - and am a raving fan of Creality. Love their printers and bang for the buck.

Ender 3 is def best entry choice in my book - low price point nice quality

Quality prints with the right setup but not as fine detailed as resin

Be prepared for initial frustrations of bed leveling. This will make or break a quality print.

Then you'll be playing with Kapton, hairspray, mirror blah blah blah to find the best surface for your prints (my goto setup for PLA is PEI on flex plate - rarely have I had a print get unstuck)

I would suggest watching some YouTube videos of people actually setting up and using their machines before you take the leap - I've seen folks get frustrated and give up and their machines never see the light of day again

-Alex