;THIS IS A TEST PROGRAM TO SEE IF I CAN PRINT TO MY

;EPSON PRINTER VIA THE PARALLEL PORT

;EPSON.ASM 2/20/2021

;THE PROGRAM FIRST SET UP THE PPI THIS CAUSES THE OUTPUT TO HIZ

;THIS CAUSES THE EPSON TO BE NOT READY AND OFFLINE

;pORT c2 IS THEM PULSED TO RESET THE EPSON THIS PUTS IT READY

;AND ONLINE THE SELECT C0 IS SET LOW

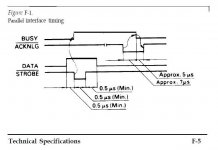

;NEXT LOOP WAITS FOR NOT BUSY (LOW) AND ACK HIGH

;WHEN THE PRINTER IS READY FOR DATA ASCII LETTERS Z-A SHOULD BE

;PRINTED THE Z IS PREPARED AND OUTPUTED NEXT STROBE C1 IS PULSED

;LOW/HIGH THE DATA LETTER IS CHANGED TO Y AND JUMPED TO LOOP

006C = PORTA EQU 06CH ;PORTA DATA OUT

006D = PORTB EQU 06DH ;PORTB STATUS IN

006E = PORTC EQU 06EH ;PORTC CTRL OUT

006F = PORTCR EQU 06FH ;MODE=0

;INPUT TO CPU

;BO = BUSY LOW = NOT BUSY

;B1 = ASKNLG HIGH = READY FOR TRANSFER

;OUTPUT TO CPU

;C0 = PLACE ON LINE, ALLOW PRINTING

;C1 = STROBE LOW = TRANSFER DATA 7 SET BUSY

;C2 = RESET LOW = RESET

0100 ORG 0100H

0100 310020 LXI SP,02000H ;SET STACK

;SET PPI FPR PORTA AS OUTPUT (DATA)

;PORTB AS INPUT (STATUS)

;PORTC AS OUTPUT (CONTROL)

START:

0103 3E82 MVI A,082H ;1000 0010

0105 D36F OUT PORTCR ;PROGRAM PPI

;PULSE PORT C2 TO RESET PRINTER TO READY & ONLINE

0107 3E03 MVI A,03H ;RESET

0109 D36E OUT PORTC

010B 3E07 MVI A,07H ;PULSE C2

010D D36E OUT PORTC

;TEST DATA WILL BE 26 CHARACTERS Z TO A

;START WITH Z AND SUBTRACT ONE UNTIL REG B IS ZERO

010F 0E41 MVI C,'A' ;TEST CHARACTER

0111 0619 MVI B,019H ;ADD 019H TO MAKE Z

;DEC REG B TO MAKE ONE LESS LETTER

;WAIT HERE FOR PRINTER TO BE NOT BUSY AND ACK HIGH

LOOP:

0113 DB6D IN PORTB ;B0 = BUSY = HIGH, NOT BUSY = LOW

0115 E603 ANI 03H ;B1 = ACK = HIGH FOR TRANSFER

0117 FE02 CPI 02H

0119 C21301 JNZ LOOP

;SET PRINTER SELECTIN LOW

011C 3E07 MVI A,07H ;SET C0 SELECT LOW

011E D36E OUT PORTC

;OUTPUT CHARACTER TO PRINT

0120 79 MOV A,C ;MOVE DATA

0121 80 ADD B

0122 D36C OUT PORTA

;PULSE PRINTER STROBE HIGH/LOW/HIGH

0124 3E05 MVI A,05H ;STROBE LOW

0126 D36E OUT PORTC

0128 00 NOP

0129 00 NOP

012A 3E07 MVI A,07H

012C D36E OUT PORTC ;STROBE HIGH

;PREPARE NEXT CHARACTER

012E 05 DCR B

012F C21301 JNZ LOOP

;QUIT

0132 C30000 JMP 00H

0135 END