thunter0512

Veteran Member

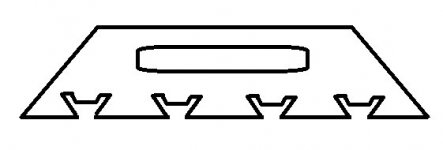

What is the best type of lubricant for Omnibus backplanes?

It can be a struggle to insert and remove PDP-8/e boards into the Omnibus.

There is a risk of damage to the brittle bakelite connector housings on the Omnibus PCB.

Traditional contact sprays should work but have two problems:

1) they remain wet and over time will attract and retain dust

2) the solvent and lubricant may weaken or attack the bakelite

There are some PTFE (Teflon) based lubricant sprays which create a dry film. Would this type of spray work?

Any suggestions what I could use which reduces the strain on the Omnibus and the PCBs during insertion/removal without creating new problems?

Thanks and best regards

Tom Hunter

It can be a struggle to insert and remove PDP-8/e boards into the Omnibus.

There is a risk of damage to the brittle bakelite connector housings on the Omnibus PCB.

Traditional contact sprays should work but have two problems:

1) they remain wet and over time will attract and retain dust

2) the solvent and lubricant may weaken or attack the bakelite

There are some PTFE (Teflon) based lubricant sprays which create a dry film. Would this type of spray work?

Any suggestions what I could use which reduces the strain on the Omnibus and the PCBs during insertion/removal without creating new problems?

Thanks and best regards

Tom Hunter