MauriceH

Experienced Member

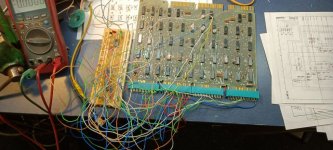

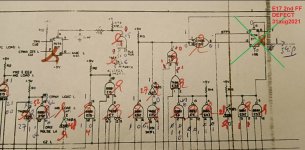

Have the PDP8/M and after some debugging and finally changing out The M8310 board I definitively know this board has a defect.

Even the simple check will fail with this board.

AC Increment

200 7001 increment Ac

201 2300 increment & skip if zero (ISZ)

202 5201 Jump 201

203 5200 Jump 200

At run the machine halt at address 0002 with AC 0000, MD 7402

Status, Link=1

State: F D E IR0 IR1 IR2 MD..

0 1 0 0 1 1 1 0 0 0 0 0

Starting at Single Step adres 200

Memory adr -- AC --- MD

0001 ...........0000...7001

0201............0000...0000

300..............0000...2300

202.............0000....0612

201............0000....5201

203..........2300....2300

200.........2300....5200

So think the problem is with AC increment,AC should become 0001 instead of zero.

Jump instruction seems to work.As in single step the jump is made to 300, So think the instruction 7001 is false.

Checked several IC's like 7474's,E40,E45,E50 and some logic's like E18.E19, E38 concerning AC lines.

Debugged lot of other logic so far no luck to find a defective one (Think it will be the last I ever will check :grin

Any Idea's would help.

Maurice

Even the simple check will fail with this board.

AC Increment

200 7001 increment Ac

201 2300 increment & skip if zero (ISZ)

202 5201 Jump 201

203 5200 Jump 200

At run the machine halt at address 0002 with AC 0000, MD 7402

Status, Link=1

State: F D E IR0 IR1 IR2 MD..

0 1 0 0 1 1 1 0 0 0 0 0

Starting at Single Step adres 200

Memory adr -- AC --- MD

0001 ...........0000...7001

0201............0000...0000

300..............0000...2300

202.............0000....0612

201............0000....5201

203..........2300....2300

200.........2300....5200

So think the problem is with AC increment,AC should become 0001 instead of zero.

Jump instruction seems to work.As in single step the jump is made to 300, So think the instruction 7001 is false.

Checked several IC's like 7474's,E40,E45,E50 and some logic's like E18.E19, E38 concerning AC lines.

Debugged lot of other logic so far no luck to find a defective one (Think it will be the last I ever will check :grin

Any Idea's would help.

Maurice