intabits

Experienced Member

There's a bunch of projects out there for "after market" and DIY boards for DEC machines, targeted at Unibus, Omnibus, Qbus, and possibly others. These projects include: extender cards, prototyping cards, Unibone, QBone, MOS memory boards, Boostrap card emulators, etc.

What they all have in common are the 36 pin edge connectors that plug into DEC equipment. And that introduces some complexity due to the need for accurate mechanical design, and the need for a non rectangular PCB. Which then increases the cost of getting them manufactured, plus the extra cost imposed by the need for gold plated fingers (of varying possible qualities and cost).

That's OK for a proven design that serves one's purposes out of the box, especially if it is something that will be always needed in a given configuration. But I'd like to experiment with my own variations of the projects mentioned above, plus others yet to be identified. I'd also like, initially at least, to make my own prototypes for these projects using DIY PCBs, and probably mostly single sided ones, as that's easier.

So it would be nice to be able to do that, but the edge connector requirements almost make it mandatory to get them made professionally, with the attendant costs and time overheads. And if there's an error in the design, the costs and delays get repeated. Also, if the particular project is only needed occasionally (eg: extenders), the costs may be a little harder to justify.

So I've been thinking about making a universal FlipChip adapter board that is basically just the edge connectors plus some other cheapo connectors that make the finger signals available to some simple rectangular (even single sided) board that plugs onto the adapter. Of course, this would need to be professionally made, double sided, with gold plating, cutouts, registered name and all the details.

But the "mating" board that plugs onto it has no such restrictions. It can be crappy as one likes, and may be just single sided, made at home in an afternoon. Even a just a bit of perfboard! If the design has errors, just make another one, ready to try out in a few hours. Once the design is sorted, and the polish of a purpose built PCB is desired, only then spend the time and money on adding the edge connectors and getting it made properly.

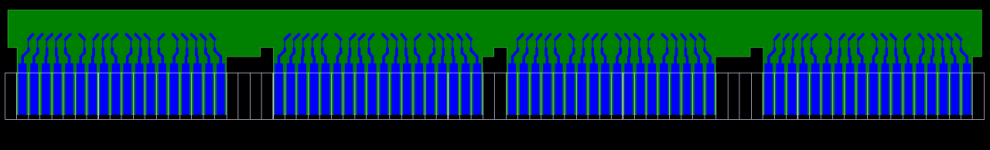

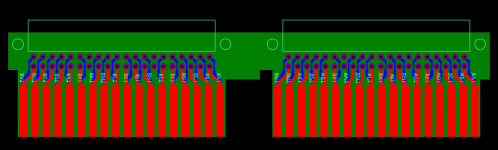

My initial design for the adapter is shown below. A double height board seems a good compromise between single, double, quad and hex. Use 2 or 3 adapters for quad or hex, get out the hacksaw for singles.

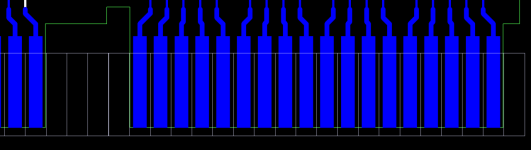

These are the sort of cheap connectors I plan to use for connecting the adapter to the mating board.

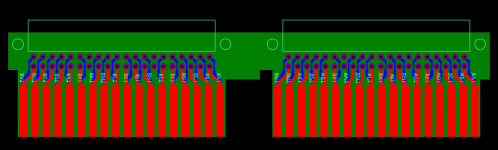

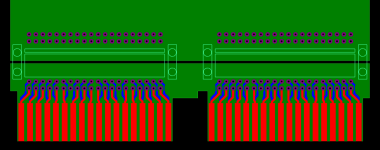

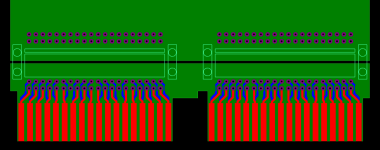

This shows how it would attach. For strength and rigidity, small straps, made of metal (or PCB or whatever) would bolt the two boards together.

I think this is a good idea, do you?

Seeking your comments and suggestions...

What they all have in common are the 36 pin edge connectors that plug into DEC equipment. And that introduces some complexity due to the need for accurate mechanical design, and the need for a non rectangular PCB. Which then increases the cost of getting them manufactured, plus the extra cost imposed by the need for gold plated fingers (of varying possible qualities and cost).

That's OK for a proven design that serves one's purposes out of the box, especially if it is something that will be always needed in a given configuration. But I'd like to experiment with my own variations of the projects mentioned above, plus others yet to be identified. I'd also like, initially at least, to make my own prototypes for these projects using DIY PCBs, and probably mostly single sided ones, as that's easier.

So it would be nice to be able to do that, but the edge connector requirements almost make it mandatory to get them made professionally, with the attendant costs and time overheads. And if there's an error in the design, the costs and delays get repeated. Also, if the particular project is only needed occasionally (eg: extenders), the costs may be a little harder to justify.

So I've been thinking about making a universal FlipChip adapter board that is basically just the edge connectors plus some other cheapo connectors that make the finger signals available to some simple rectangular (even single sided) board that plugs onto the adapter. Of course, this would need to be professionally made, double sided, with gold plating, cutouts, registered name and all the details.

But the "mating" board that plugs onto it has no such restrictions. It can be crappy as one likes, and may be just single sided, made at home in an afternoon. Even a just a bit of perfboard! If the design has errors, just make another one, ready to try out in a few hours. Once the design is sorted, and the polish of a purpose built PCB is desired, only then spend the time and money on adding the edge connectors and getting it made properly.

My initial design for the adapter is shown below. A double height board seems a good compromise between single, double, quad and hex. Use 2 or 3 adapters for quad or hex, get out the hacksaw for singles.

These are the sort of cheap connectors I plan to use for connecting the adapter to the mating board.

This shows how it would attach. For strength and rigidity, small straps, made of metal (or PCB or whatever) would bolt the two boards together.

I think this is a good idea, do you?

Seeking your comments and suggestions...