Westinghouse

New Member

Hi all,

I recently acquired an Osborne 1b.

It's got both the ScreenPac board and the Double Density board.

I've addressed a number of issues with it already.

Within 15 minutes of my first use, it blew the paper caps and the fuse in the PSU; these were replaced.

I adjusted the display size on the monitor, which was a little overly large for the bezel.

The last issue, which continues to frustrate me, is that the B> drive is not functioning properly.

I've done quite a few things to try to correct this; bear with me as I lay this out.

The spindle motor on B> was audibly slow, and would throw BOOT ERRORs if trying to boot from it, and BDOS errors when accessing B> after sucessfuly booting off of A>.

The motor would actually slow right down to stopping if I let the BOOT ERRORs add up.

I opened the Osborne and swapped around some components.

Let's call the drive PC boards 'A Board' and 'B Board', and the other drive hardware components 'A Chassis' and 'B Chassis'.

A Board + A Chasiss -- works in both A> and B> positions.

B Board + B Chassis -- fails in both A> and B> positions.

A Board + B Chassis -- works in both A> and B> positions.

B Board + A Chassis -- fails in both A> and B> positions.

I don't have an oscilloscope, but I took voltage readings from several sites.

Voltage is generally as described in Sam's Computerfacts, with the following exceptions:

- Supply to R24 is constant and at the expected voltage, but on the other side of R24 the voltage slowly drops.

- Supply to Pins 6 + 7 on U10 (the 555 timer) slowly drops - this is downcircuit of R24.

- Voltage on Pin 3 of U10 slowly drops.

- Voltage on Pin 9 of U18 slowly drops.

- Voltage on the anode side of D7 slowly drops; cathode side is correct voltage and constant.

The voltage drop eventually, over a series of minutes, gets to the point where the spindle motor stops.

It seems to have a cool-down period; leaving it alone for a few minutes gets the voltages back up somewhat; a longer period will get it back to initial conditions -- but under load, the drop always happens.

I've replaced a number of the components in these areas, to no effect.

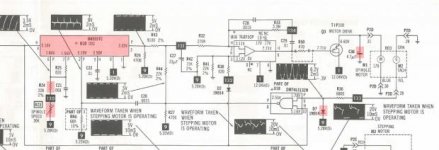

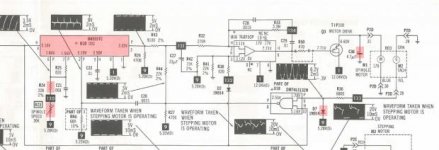

In the attached image, the components that I have replaced are shaded red.

If I reduce the resistance at R23, the spindle will start off too fast, but after slowing down a bit, the drive will stop throwing BOOT ERRORs and actually boot to a prompt; this usually only lasts long enough to execute a DIR command before the spindle motor becomes too slow. This leads me to believe that the stepper motor part of the circuit is fine.

The gradual voltage dropoff and associated cool-down period have me thinking it might be a component heating up, but the only element which seems to show any appreciable temperature increase is the TIP110 riveted to the heatsink and PCB.

I'd be really appreciative of any advice, as I'm kind of stumped.

I recently acquired an Osborne 1b.

It's got both the ScreenPac board and the Double Density board.

I've addressed a number of issues with it already.

Within 15 minutes of my first use, it blew the paper caps and the fuse in the PSU; these were replaced.

I adjusted the display size on the monitor, which was a little overly large for the bezel.

The last issue, which continues to frustrate me, is that the B> drive is not functioning properly.

I've done quite a few things to try to correct this; bear with me as I lay this out.

The spindle motor on B> was audibly slow, and would throw BOOT ERRORs if trying to boot from it, and BDOS errors when accessing B> after sucessfuly booting off of A>.

The motor would actually slow right down to stopping if I let the BOOT ERRORs add up.

I opened the Osborne and swapped around some components.

Let's call the drive PC boards 'A Board' and 'B Board', and the other drive hardware components 'A Chassis' and 'B Chassis'.

A Board + A Chasiss -- works in both A> and B> positions.

B Board + B Chassis -- fails in both A> and B> positions.

A Board + B Chassis -- works in both A> and B> positions.

B Board + A Chassis -- fails in both A> and B> positions.

I don't have an oscilloscope, but I took voltage readings from several sites.

Voltage is generally as described in Sam's Computerfacts, with the following exceptions:

- Supply to R24 is constant and at the expected voltage, but on the other side of R24 the voltage slowly drops.

- Supply to Pins 6 + 7 on U10 (the 555 timer) slowly drops - this is downcircuit of R24.

- Voltage on Pin 3 of U10 slowly drops.

- Voltage on Pin 9 of U18 slowly drops.

- Voltage on the anode side of D7 slowly drops; cathode side is correct voltage and constant.

The voltage drop eventually, over a series of minutes, gets to the point where the spindle motor stops.

It seems to have a cool-down period; leaving it alone for a few minutes gets the voltages back up somewhat; a longer period will get it back to initial conditions -- but under load, the drop always happens.

I've replaced a number of the components in these areas, to no effect.

In the attached image, the components that I have replaced are shaded red.

If I reduce the resistance at R23, the spindle will start off too fast, but after slowing down a bit, the drive will stop throwing BOOT ERRORs and actually boot to a prompt; this usually only lasts long enough to execute a DIR command before the spindle motor becomes too slow. This leads me to believe that the stepper motor part of the circuit is fine.

The gradual voltage dropoff and associated cool-down period have me thinking it might be a component heating up, but the only element which seems to show any appreciable temperature increase is the TIP110 riveted to the heatsink and PCB.

I'd be really appreciative of any advice, as I'm kind of stumped.

Last edited: