(Originally posted this on 68kmla but got recommended to post it over here by a friend of mine, hopefully any of you can help me out!)

I've recently bought a troubled Macintosh SE/30 for way too much money.

(Issues with HDD, FDD, motherboard with extremely leaky battery and now also the CRT lol....)

I'm still working on some of the issues and waiting on replacement capacitors, the ugliest ones have been replaced but with the audio being extremely faint too I think all of them are in dire need.

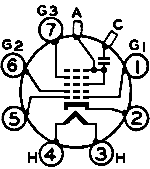

Anyways, I'm making this topic to get some feedback on how to resolve this issue with the CRT. The image seems to "ghost" or affect the image to the right, its not extremely heavy but its enough to kinda bother me.

The alignment and geometry of it is mint, extremely pleasing to look at.

Not sure if this is related, but pressing the reset button very clearly shows the horizontal sync collapsing, resulting in a "lightning strike"

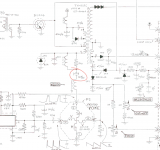

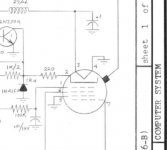

Analog board looks good from a glance, but I haven't removed it as the internet made me afraid to work on high voltage stuff like CRTs

I've recently bought a troubled Macintosh SE/30 for way too much money.

(Issues with HDD, FDD, motherboard with extremely leaky battery and now also the CRT lol....)

I'm still working on some of the issues and waiting on replacement capacitors, the ugliest ones have been replaced but with the audio being extremely faint too I think all of them are in dire need.

Anyways, I'm making this topic to get some feedback on how to resolve this issue with the CRT. The image seems to "ghost" or affect the image to the right, its not extremely heavy but its enough to kinda bother me.

The alignment and geometry of it is mint, extremely pleasing to look at.

Not sure if this is related, but pressing the reset button very clearly shows the horizontal sync collapsing, resulting in a "lightning strike"

Analog board looks good from a glance, but I haven't removed it as the internet made me afraid to work on high voltage stuff like CRTs