I also generally agree with "if it ain't broke, don't fix it.". The exception might be the high voltage RFI capacitors. Those should be replaced if possible. I have been meaning to do that on my Compaq Portable, but the power supply is impossible to get to unless the entire unit it totally disassembled. Even if you think it really needs it, it is probably best to start with the high-frequency capacitors in the power supply and the CRT analog board. Very little reason to mess with anything on the motherboard or cards unless there is a specific problem.

Some machines like early Macintosh or IBM PS/2 floppy drives have known issues with "leaky" or crappy capacitors that must be addressed. I've never heard of any specific issues with the Compaq Portable/Plus.

So a few things to keep in mind:

-There is a high risk of botching solder pads, traces, or vias when de-soldering components.

-Damage can occur if the wrong component is used or if it is installed wrong.

-Some systems may have errors in their schematics, PCB silk-screen, or on component labeling. (There was a thread recently about an Apple IIc CRT that had a capacitor marking backwards)

-Vendors sometimes selected individual parts based on their own tests of unlabeled properties. You may have no way to know what those properties were. (a bigger issue with ICs)

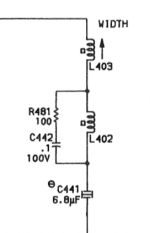

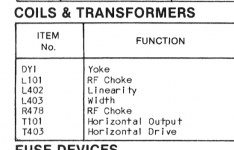

At any rate, I happened to be repairing a damaged CRT board on another luggable, I was looking up components the other day, so here are my thoughts.

Yes, places like Mouser may have many part numbers for the same rated item. It can be very confusing. It may be different for something as minor as packaging. For hobbyists it doesn't matter if a part is individual bulk or on an ammo-pack strip, but for others that is important.

Brand: Any of the major Japanese bands are fine.

Form/Termination style: Surface mount, radial, axial, etc. For vintage purposes, usually simple radial or axial. Wrong one just won't fit.

General type: Watch out for bi-polar capacitors. (They are all off their meds

)

Capacitance rating: Nothing odd here.

Voltage rating: Generally use the same rating. If needed, or desired you can bump the rated voltage up a notch as long as the part will still fit. Keep in mind that an original part installed may have already been bumped up due to supply.

Operating Temperature: Usually 85C for vintage needs. Generally use the same rating. Bumping it up won't hurt, as long as the part fits. Again, original installed parts may have been bumped up due to supply.

Tolerance: Usually 20%, this is not always on a capacitor label. Going higher won't hurt.

Length/width/diameter/lead spacing: Newer capacitors may be smaller than older capacitors. Some capacitors may be intentionally designed to be taller or wider for specific installation environments. If the lead spacing differs from the PCB it won't sit flush against the PCB - usually only an issue or larger capacitors or when there is limited space.

Series: Not important to us.

Ripple current: Higher is "better" but usually does not matter for vintage stuff.

Life rating: A longer usage life rating is nice, but not too important for something that is only turned on occasionally.

Certifications: Doesn't matter at all for vintage needs.

Leakage Current: Lower better. Anything new should be good enough for anything used in vintage stuff.

There might be supply issues on some parts. So they might have the "perfect" matched part listed but out of stock. They also tend to list non-stocked and obsolete items for reference that are not carried any more and will not be stocked.

On Mouser's web site, you can do a "side by side" comparison to help show you the minute differences. Other sites may not be as friendly.