glitch

Veteran Member

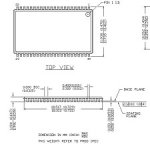

I just finished laying this guy out and sending off to OSH Park for prototypes:

It's a mezzanine board that should bolt to any XT-IDE that uses the Keystone 9202 ISA bracket, including rev 1 - 4, the one Lo-tech board that uses it, derivatives that use the bracket, and of course the knockoffs that have shown up on eBay The adapter is designed to mount on small standoffs that screw down in place of the Philips head screws that normally hold the bracket on, making the CF card accessible through the ISA slot. I'll probably provide a drill/cut template for folks who want to modify their own brackets, as well as modified Keystone brackets for those who just want a drop-in replacement.

The adapter is designed to mount on small standoffs that screw down in place of the Philips head screws that normally hold the bracket on, making the CF card accessible through the ISA slot. I'll probably provide a drill/cut template for folks who want to modify their own brackets, as well as modified Keystone brackets for those who just want a drop-in replacement.

Paired with a Slot 8 Support module, this should be pretty handy for XTs and 5155 PC Portables where rear CF access is desirable.

The mezzanine cables to the XT-IDE with a regular old IDE cable, so you can also hook on a second device. There's a master/slave jumper on the adapter, but a lot of CF cards don't want to be anything but master. 5V power is taken from IDE pin 20, which of course the XT-IDEs have supported for a while. Boards that don't support it can be modified easily.

The board is laid out for a 3M CompactFlash adapter, available from the usual sources. It's $4-5 each for the 3M part, depending on how many you buy, but it's a high quality CF slot. I'll be providing the boards, parts kits, or fully assembled, so even if you don't want to do surface mount soldering, you can have a CF mezzanine for your XT-IDE.

It's a mezzanine board that should bolt to any XT-IDE that uses the Keystone 9202 ISA bracket, including rev 1 - 4, the one Lo-tech board that uses it, derivatives that use the bracket, and of course the knockoffs that have shown up on eBay

Paired with a Slot 8 Support module, this should be pretty handy for XTs and 5155 PC Portables where rear CF access is desirable.

The mezzanine cables to the XT-IDE with a regular old IDE cable, so you can also hook on a second device. There's a master/slave jumper on the adapter, but a lot of CF cards don't want to be anything but master. 5V power is taken from IDE pin 20, which of course the XT-IDEs have supported for a while. Boards that don't support it can be modified easily.

The board is laid out for a 3M CompactFlash adapter, available from the usual sources. It's $4-5 each for the 3M part, depending on how many you buy, but it's a high quality CF slot. I'll be providing the boards, parts kits, or fully assembled, so even if you don't want to do surface mount soldering, you can have a CF mezzanine for your XT-IDE.