I recently acquired an Altair 8800 from a fellow Ham. This was a unit that was in actual business use 40+ years ago, and had been updated to be able to run perhaps CP/M or the Cromix Operating System.

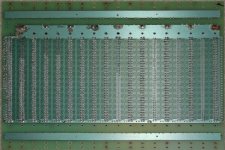

The system has just 3 cards in it, the ZPU board (Z80) from Cromemco, the 64KZ Dynamic RAM board also from Cromemco and the Cromemco 4FDC floppy disk controller (which also provides the rs232 terminal port & RDOS in ROM). There is a separate enclosure with 2 8” floppy drives in it, which will be the next restoration project.

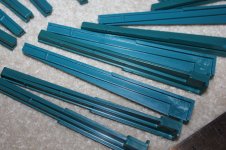

Luckily it had been stored away and had avoided getting recycled or thrown away! Unfortunately during storage it was subjected to rodent nesting for some time. Below are some photos of the starting point of my restoration project. The view down into the back plane board is taken after I grabbed a huge ball of mouse mess that filled the entire free space between the cards.

My thinking is to restore it to the state where it was when it was last in use and perform some testing with the front panel to verify basic functioning of the system. The next step would be to select boot into the RDOS monitor and have some fun operating the Altair using a terminal emulator in my PC. The RDOS monitor is very focused on Disk operations, which will come in handy after I restore the diskette drives. To begin with, it will be fun to see if RDOS will allow me to upload things like Altair games or Altair basic into memory and execute them.

The first step will be to dismantle the Altair to the point that it is possible to get rid of the rodent mess. The cards & front panel look to be in pretty good shape and will only need a thorough cleaning. Is washing with dish soap recommended? If so, should all IC’s be pulled?

The back plane (motherboard) and power supply look very iffy. There is a lot of corrosion in the card edge connectors of the back plane. I will probably have to unsolder all the power supply wires & front panel wires from the back plane (ugh!), treat the connectors with a contact cleaner & do a really thorough clean with dish soap & water, followed by isopropyl alcohol rinse & drying.

What contact cleaner is recommended for such a task?

The power supply will have to be cleaned and recapped. One of the transformers has some damage from the rodents but I am hoping it is limited to just the top insulation layer. If all else fails, there’s always the option of installing modern switch mode supplies.

Any comments or advice guys? This is my first vintage computer restoration project - wish me luck!

-ilkka

The system has just 3 cards in it, the ZPU board (Z80) from Cromemco, the 64KZ Dynamic RAM board also from Cromemco and the Cromemco 4FDC floppy disk controller (which also provides the rs232 terminal port & RDOS in ROM). There is a separate enclosure with 2 8” floppy drives in it, which will be the next restoration project.

Luckily it had been stored away and had avoided getting recycled or thrown away! Unfortunately during storage it was subjected to rodent nesting for some time. Below are some photos of the starting point of my restoration project. The view down into the back plane board is taken after I grabbed a huge ball of mouse mess that filled the entire free space between the cards.

My thinking is to restore it to the state where it was when it was last in use and perform some testing with the front panel to verify basic functioning of the system. The next step would be to select boot into the RDOS monitor and have some fun operating the Altair using a terminal emulator in my PC. The RDOS monitor is very focused on Disk operations, which will come in handy after I restore the diskette drives. To begin with, it will be fun to see if RDOS will allow me to upload things like Altair games or Altair basic into memory and execute them.

The first step will be to dismantle the Altair to the point that it is possible to get rid of the rodent mess. The cards & front panel look to be in pretty good shape and will only need a thorough cleaning. Is washing with dish soap recommended? If so, should all IC’s be pulled?

The back plane (motherboard) and power supply look very iffy. There is a lot of corrosion in the card edge connectors of the back plane. I will probably have to unsolder all the power supply wires & front panel wires from the back plane (ugh!), treat the connectors with a contact cleaner & do a really thorough clean with dish soap & water, followed by isopropyl alcohol rinse & drying.

What contact cleaner is recommended for such a task?

The power supply will have to be cleaned and recapped. One of the transformers has some damage from the rodents but I am hoping it is limited to just the top insulation layer. If all else fails, there’s always the option of installing modern switch mode supplies.

Any comments or advice guys? This is my first vintage computer restoration project - wish me luck!

-ilkka