voidstar78

Veteran Member

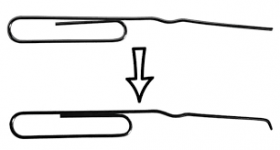

So, I search around on this - when you search "how to use a dip switch" you get results that talk about placing it on a breadboard, connecting resistors, and directing flow of electricity, etc.. Which is a perfectly correct answer to the question.

But I'm really trying to ask is: what is the "correct" way to flip the switch on a dip switch.

I know how to flip the dip switches. My question is, how do YOU flip your dip switches?

Some people use a pen, but then that leaves a mark revealing that "someone has mucked with these dip switches!"

Personally, I wouldn't use a needle - but if the power is off, well, maybe that's fine.

I use a toothpick. But, some dip switches are pretty stout and I end up breaking toothpicks. And, a toothpick can still "nick" a dip switch and leave a little mark or indentation.

Maybe those little floss sticks would be better?

Obviously, just use whatever works for whatever situation you're in.

But, is there an "official" way? Is there some $100 purpose built tool, with felt lining that is so posh it won't ever leave any mark and fits perfectly within the slot?

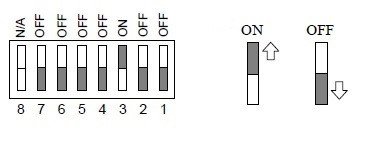

And I'm talking about "normal" dip switches. Hmmm, what's "normal." I suppose I mostly mean those "piano" style DIP switches.

Thoughts? I confess, it annoys me sometimes to see nicked up dip switches, it's like The Three Little Bears Story "someone's been fiddling with my dip switches!"

But I'm really trying to ask is: what is the "correct" way to flip the switch on a dip switch.

I know how to flip the dip switches. My question is, how do YOU flip your dip switches?

Some people use a pen, but then that leaves a mark revealing that "someone has mucked with these dip switches!"

Personally, I wouldn't use a needle - but if the power is off, well, maybe that's fine.

I use a toothpick. But, some dip switches are pretty stout and I end up breaking toothpicks. And, a toothpick can still "nick" a dip switch and leave a little mark or indentation.

Maybe those little floss sticks would be better?

Obviously, just use whatever works for whatever situation you're in.

But, is there an "official" way? Is there some $100 purpose built tool, with felt lining that is so posh it won't ever leave any mark and fits perfectly within the slot?

And I'm talking about "normal" dip switches. Hmmm, what's "normal." I suppose I mostly mean those "piano" style DIP switches.

Thoughts? I confess, it annoys me sometimes to see nicked up dip switches, it's like The Three Little Bears Story "someone's been fiddling with my dip switches!"