So I bought all the caps from mouser and they are listed below if interested (ones left out I already had in my inventory).

http://www.mouser.com/ProductDetail...mDNgx1uK8/A==&countrycode=US¤cycode=USD

http://www.mouser.com/ProductDetail...Sg6rX7oMz0g==&countrycode=US¤cycode=USD

http://www.mouser.com/ProductDetail...C6%2bGA5Zeg==&countrycode=US¤cycode=USD

The large single cap has been a point of contention in that finding the correct value in such a short and stubby size to fit in the psu case is pretty difficult. I ended up buying these as they are the shortest i can find at 25MM :

http://www.mouser.com/ProductDetail...inuxkT3hj8Q==&countrycode=US¤cycode=USD

In the end they are taller in that (due to them being wider than the original, we will get to that.

So I have done two psus already and they work. I started off doing the worst one first. IT was severely rusty and the PCB was very corroded due to the cap leakage and whatever else rusted the psu case. The traces seemed ok enough to warrant the repair.

First off the unit works now and outputs good power, however the PSU (not the internal speaker) is outputting alot of audible whine. This may be due to grounding as the metal case is still soaking in vinegar until I can de-rust and paint it. Im using an alligator clip to work as ground for now. So like I said the unit outputs good power but there is whine. I will update on that when I finish restoring the psu case.

The second unit is much like the rest in my pile. The caps have all leaked and the bottom side of the pcb (low voltage side) shows corrosion on the solder and traces from cap leakage, but nothing terrible.)

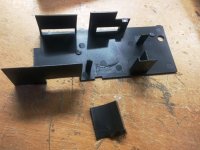

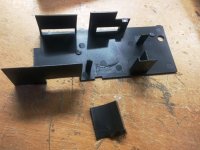

So I put the unit back together in the case. I had to use flush cutters to cut the semi-cylindrical tabs of the plastic insultation trays because the new cap is wider.

I then put the the plastic trays in the metal case and put the PSU back together. The 5 machine screws all go back in with just a bit of coaxing. Driving the screws in will bring the case back together again. As seen here is looks fine, there is only the slightest area towards the back where only one lone screw holds the case together that shows bulging.

The psu works and there is no shorting and no evidence anything is too tight and may wear over time.

Now going back to what I said about the cap ending up being more than 25mm. I didnt take into account the new caps's width which is just wide enough to warrant the previous tabs to be removed as well as it encroaching upon a few components nearby. The cap ends up hanging over slighly some components circles in read here:

I cut a square of large heatshrink material to place under the cap to insulate it from these components.

In the end this raised the height 2 or 3 mm.

End the end it worked out. Im sure there are caps that would fit better but I am ok with these.